News

Disposable vs Reusable Surgical Consumables: Procurement Comparison for Global Buyers

Disposable vs Reusable Surgical Consumables: Procurement Comparison for Global Buyers

A procurement-focused comparison of disposable surgical consumables and reusable medical devices, covering infection control considerations, regulatory requirements, workflow integration, and OEM sourcing strategies for global distributors and healthcare institutions.

Understanding Disposable vs Reusable Surgical Consumables

In modern operating rooms (OR), procurement teams often evaluate whether to source single-use disposable surgical consumables or reusable medical devices.

This decision typically involves infection control protocols, sterilization workflow capacity, regulatory compliance, cost structure, and supply chain reliability.

Key Differences Between Disposable and Reusable Systems

Disposable Surgical Consumables

- Single-use sterile packaging

- No reprocessing required

- Standardized OR workflow integration

- Reduced sterilization validation procedures

- Often sourced through OEM / private labeling programs

Reusable Medical Devices

- Requires cleaning and sterilization workflow

- Longer lifecycle per unit

- Validated reprocessing documentation required

- Institutional maintenance protocols

- Higher initial capital investment

Infection Control and Regulatory Considerations

- Alignment with hospital infection control policies

- Traceability and SKU documentation

- CE MDR and ISO 13485 compliance

- Regional registrations (FDA / NMPA / others)

- Validated sterilization labeling (EO sterilized)

Cost Structure and Supply Chain Evaluation

Disposable Model

Predictable per-case cost structure, simplified inventory management, and streamlined export logistics.

Reusable Model

Requires long-term maintenance budgeting, sterilization infrastructure, and validated cleaning documentation.

How Global Buyers Make the Procurement Decision

- Institutional infection control requirements

- Procedure volume and OR capacity

- Central sterilization department resources

- OEM supply chain stability

- Private labeling opportunities

- Long-term regulatory risk management

Related Disposable Surgical Consumable Categories

Frequently Asked Questions

Are disposable surgical consumables safer than reusable devices?

Disposable devices eliminate reprocessing steps, which may simplify infection control workflows depending on institutional protocols.

Why do many hospitals choose single-use surgical devices?

Single-use devices offer predictable cost structure, sterile packaging, and simplified workflow integration.

Are disposable consumables more expensive long term?

Cost evaluation depends on procedure volume, sterilization infrastructure, and supply chain efficiency.

Can disposable surgical consumables be supplied through OEM programs?

Yes, many manufacturers offer OEM and private labeling programs for global markets.

What certifications are required for global distribution?

Common certifications include CE MDR compliance and ISO 13485 quality systems.

OEM Disposable Surgical Consumables Manufacturer for Global Distribution

As a professional disposable surgical consumables manufacturer, we support global distributors and medical device brands with CE MDR and ISO 13485 compliant OEM production.

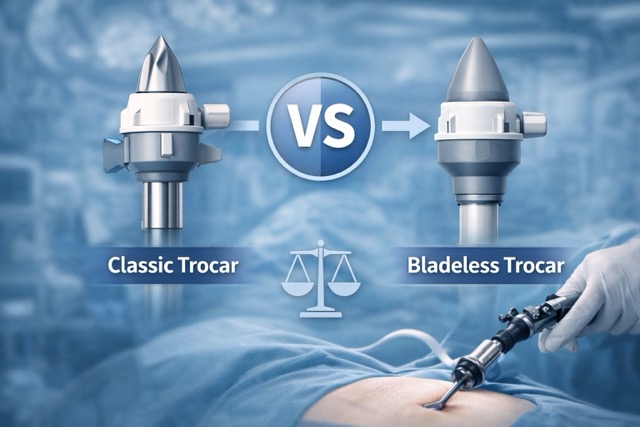

Our product portfolio includes laparoscopic fluid management systems, insufflation filters, smoke evacuation sets, specimen retrieval bags, trocar systems, and OR safety consumables designed for standardized operating room workflows.

We provide scalable manufacturing, private labeling services, and export-ready packaging solutions for long-term international partnerships.